Product Description:

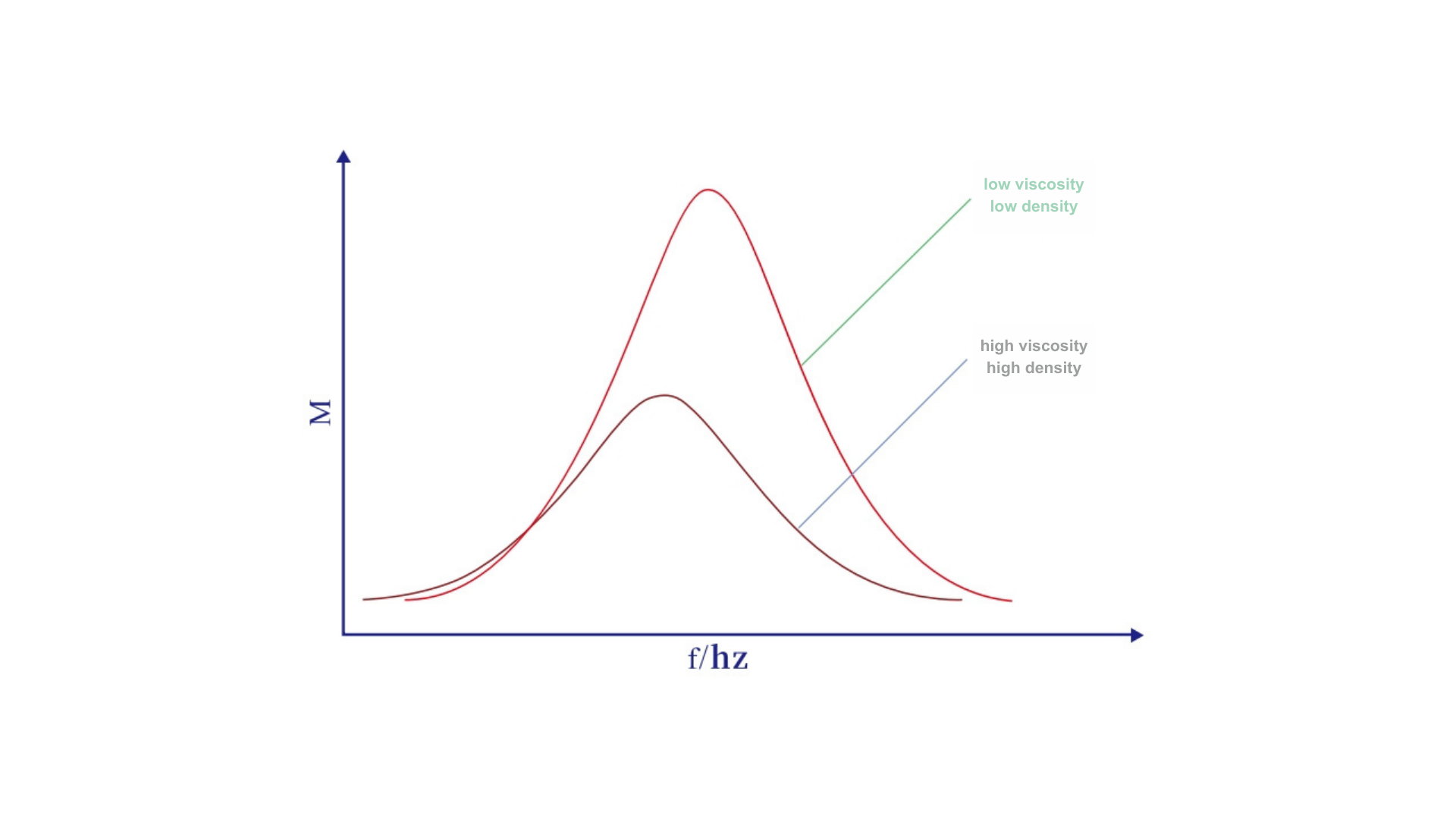

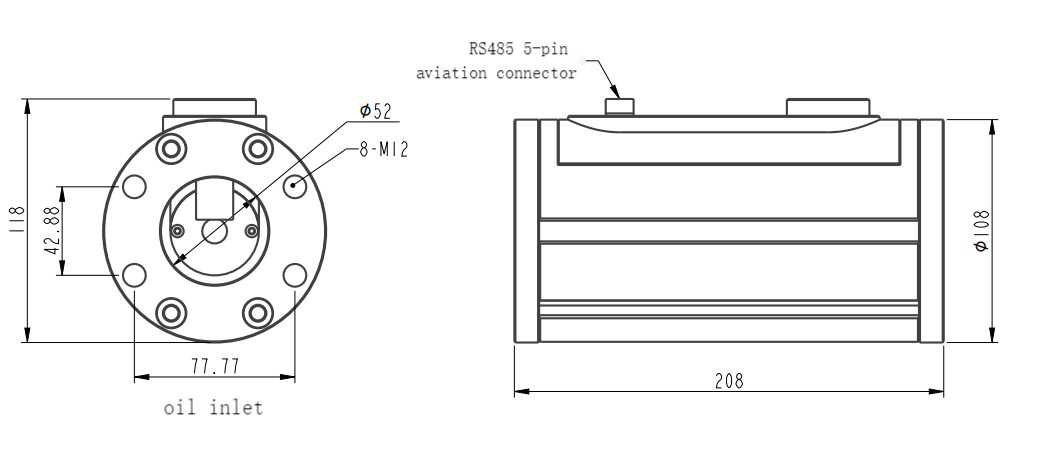

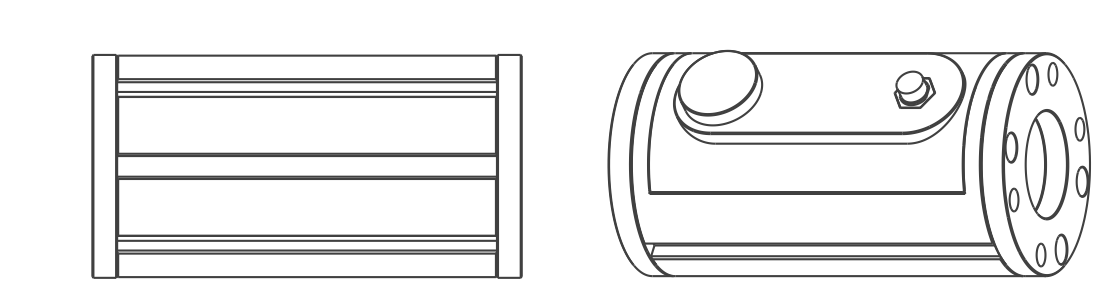

JW-V6M8S2 multi-functional oil condition sensor for wind turbine gearbox is a highly integrated oil condition monitoring device, integrating multiple detection components such as ferromagnetic and non-ferromagnetic metal wear particles, viscosity, density, temperature, water activity, and micro moisture content. It can also be optionally equipped with dielectric constant and free water detection components to achieve integrated detection of oil wear state and oil product characteristics. This sensor is compact and robust in structure, making it particularly suitable for monitoring the oil condition of wind turbine gearboxes and other heavy industrial equipment. It is an ideal choice for preventive maintenance and advanced intelligent manufacturing fields.

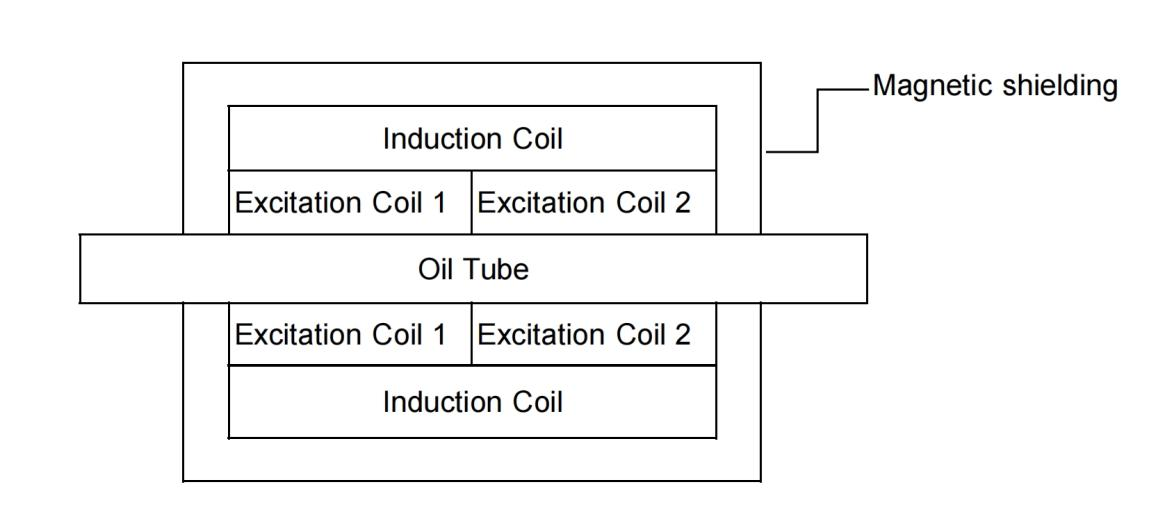

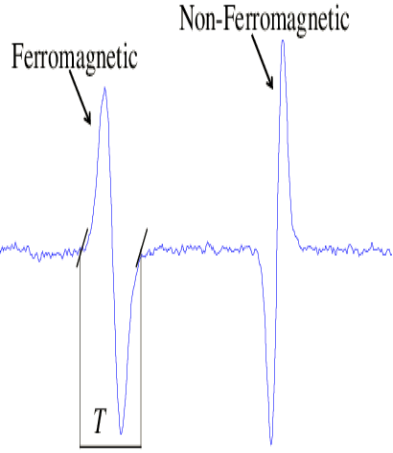

It is equipped with an industry-leading high-precision and high-stability metal wear particle detection component. It adopts Faraday's electromagnetic induction principle and combines a high-performance data acquisition and processing unit to capture and cumulatively count ferromagnetic particles (≥40μm) and non-ferromagnetic metal particles (≥150μm) in the oil in real time. This function provides precise data support for real-time monitoring of equipment wear status, helping users achieve predictive maintenance and reduce the risk of equipment failure.

JW-V6M8S2 also integrates the functions of internal temperature measurement and oil flow velocity measurement. It realizes the self-check of the sensor's working environment and the judgment of the fluidity of the oil circuit, always ensuring that the sensor works in a good detection state and the representativeness of the detected oil samples.

JW-V6M8S2 realizes the real-time monitoring of the wear conditions of wind power gearboxes and other heavy industrial equipment. By continuously monitoring the generation of wear debris and the detection of physical and chemical indicators of oil products, it is convenient to remind users when early faults of the equipment are discovered. Compared with the traditional maintenance schedule, lower-cost maintenance measures have been achieved and more serious accidents have been prevented.