Email: info@joinwesmart.com

Tel: +86 186 8032 9994

-

HOME

-

PRODUCTS

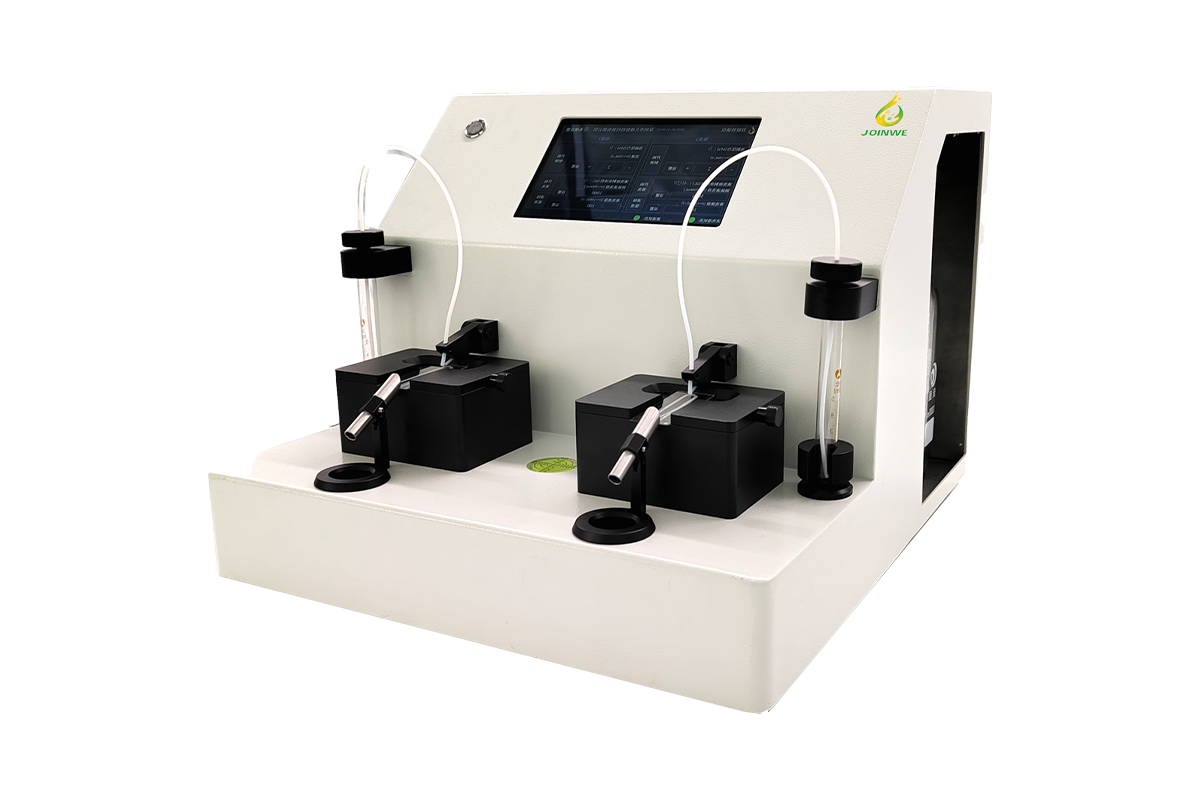

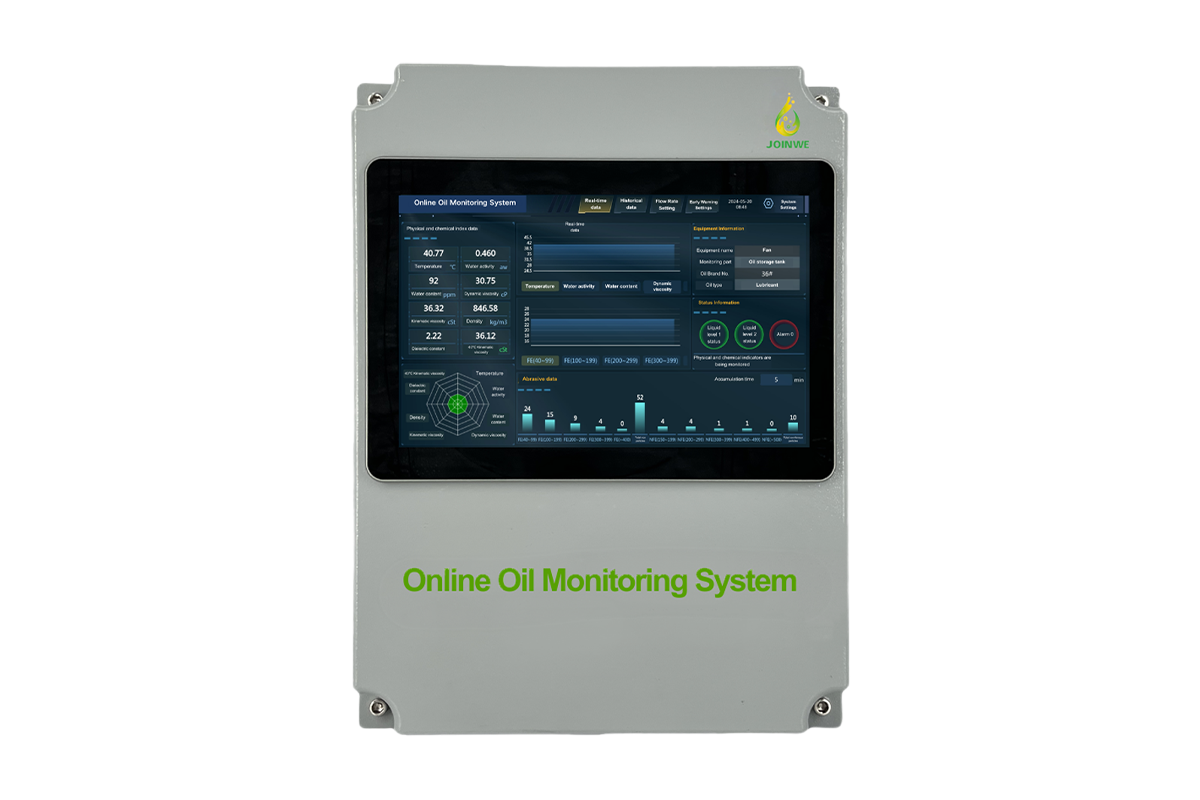

Online Oil Monitoring SystemJW-Online Online Oil Monitoring System JWA2-M Oil Micro Moisture Sensor JWB2-MC Moisture Content Sensor JWFV6 6-in-1 Oil Condition Sensor JWFV4 4-in-1 Oil Condition Sensor JWFV3 3-in-1 Oil Condition Sensor JWF2-Q Oil Quality Sensor JWJ4 Online Particle Counter Sensor JWMA-W Adsorption Wear Particle Sensor JWM8 Metal Wear Particle Sensor JW-V6M8S2 Oil Condition Sensor for Wind Turbine Gearbox JW-V6M8S Oil Condition Sensor for Wind Turbine Gearbox

-

APPLICATIONS

- NEWS

-

ABOUT

-

CONTACT

-

FAQ

- DOWNLOAD