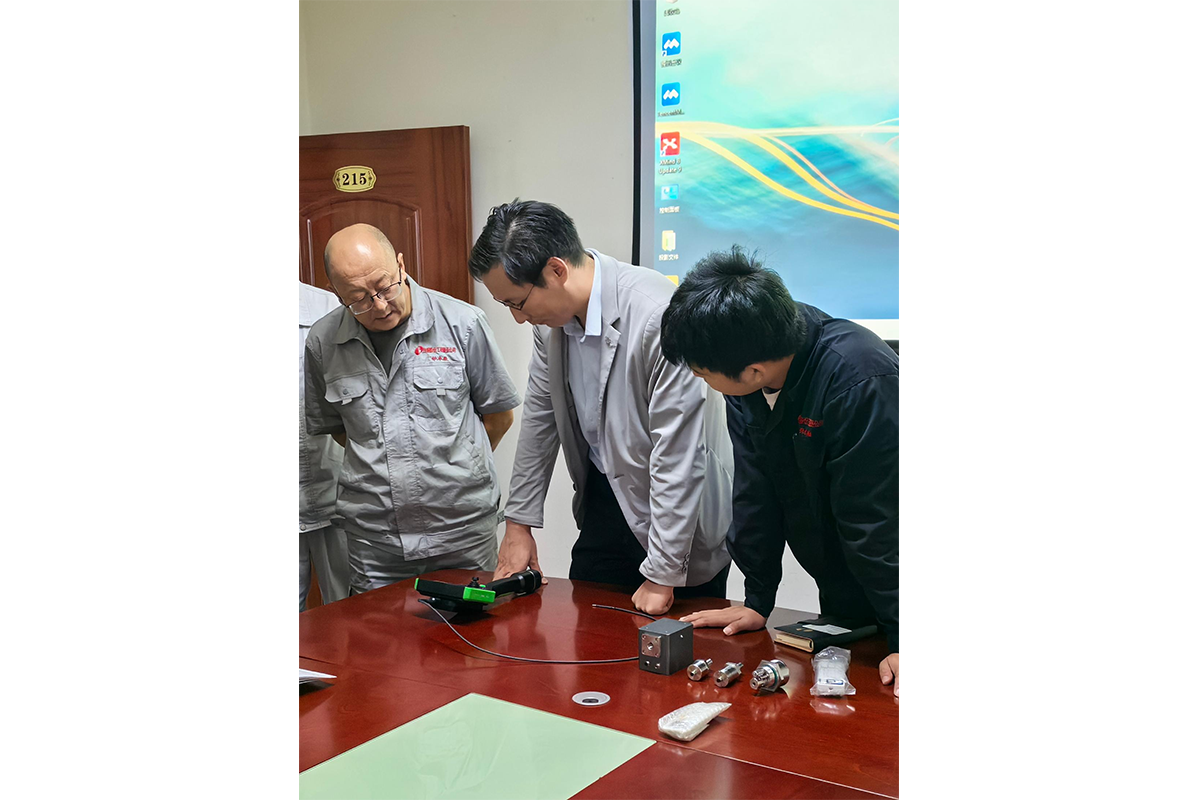

The JW-G Series mechanical industrial videoscope is a specialized inspection device used for high-precision visual inspection in mechanical and industrial applications—especially where direct visual access is impossible.

Unlike a basic borescope, a videoscope has an integrated camera and video display that transmits real-time, high-resolution images, and often includes mechanical articulation to control the camera head’s viewing angle remotely.

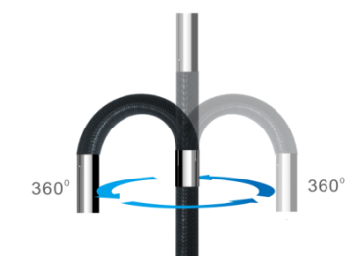

• 360° guidance with mechanical joystic.

• The intelligent platform has a user-friendly and intuitive interface, video and picture annotation, tagging and other functions, built-in document management software and user manuals.

• 5.5-inch OLED touch screen, wider viewing angle, clearer display and more realistic color reproduction; Even in strong sunlight, subtle defects can also be detected.

More information on industrial endoscope operation guides

Mechanical Industrial Videoscope Features:

1. RK3588 high-performance processor with 4x Cortex-A76 and 4x Cortex-A55 cores. Provides superior computational and graphic processing power.

2.High-definition megapixels, new digital high-definition image processing technology, ultra-clear images.

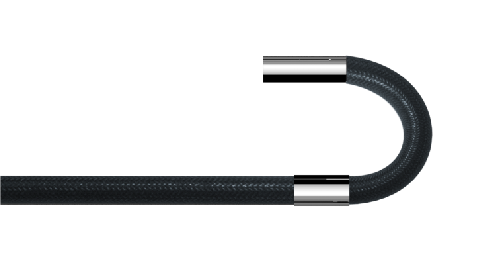

3. Probe of IP67 rating, capable of adapting to extreme inspection environments.

4. It is possible to replace the insertion tubes with different specifications in one click, which can satisfy different on-site applications.

5. Flexible articulation -mechanical 360°steering function,one-way bending can be up to 180°.

Other function:

• Add tags: Use the small joystick to add markers when recording video, and view the video to quickly locate the marker point.

• Black box: Turn on real-time recording in the settings, the operation screen will be recorded automatically, and you can customize the recording duration.

• Generate test report: It can select images and generate PDF documents.

How It Works

Insert the videoscope probe into the inspection point (engine port, pipe opening, etc.).

Use mechanical articulation to steer the camera head toward areas of interest.

View live images on the built-in screen.

Adjust LED brightness to optimize image clarity.

Capture photos or video for later analysis.

Applications

Mechanical Engineering – Checking gearboxes, bearings, and internal components without disassembly.

Automotive – Inspecting engines, cylinders, and exhaust systems.

Aerospace – Examining turbine blades, combustion chambers, and fuel systems.

Industrial Manufacturing – Quality control and weld inspection inside tanks and pipelines.

Energy Industry – Inspecting boilers, heat exchangers, and turbines.

In addition to mechanical industrial endoscopes, we also offer motorized industrial endoscopes.