JOINWE HD Industrial Videoscope Empowers Guangzhou DATAMATIC Mould with Fast, Efficient Pipeline Inspection

Injection molds are the core equipment of injection molding production, and the accuracy and cleanliness of mold channels directly determine the quality of injection-molded products. As a professional mold manufacturer, DATAMATIC CNC ENGINEERING CO., LTD. faced critical challenges in inspecting mold channels during production.

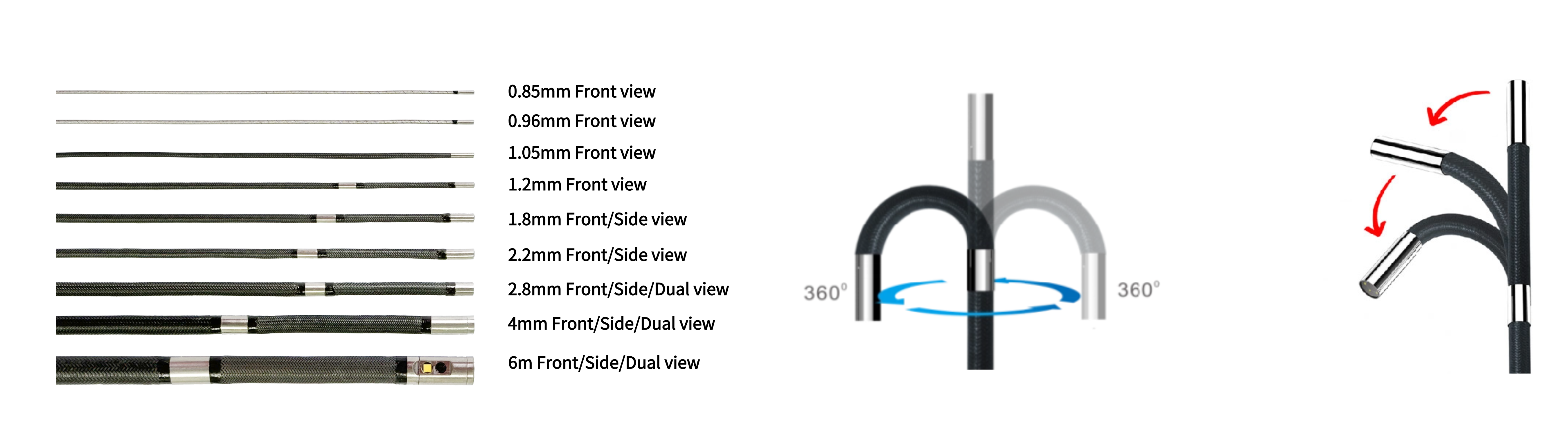

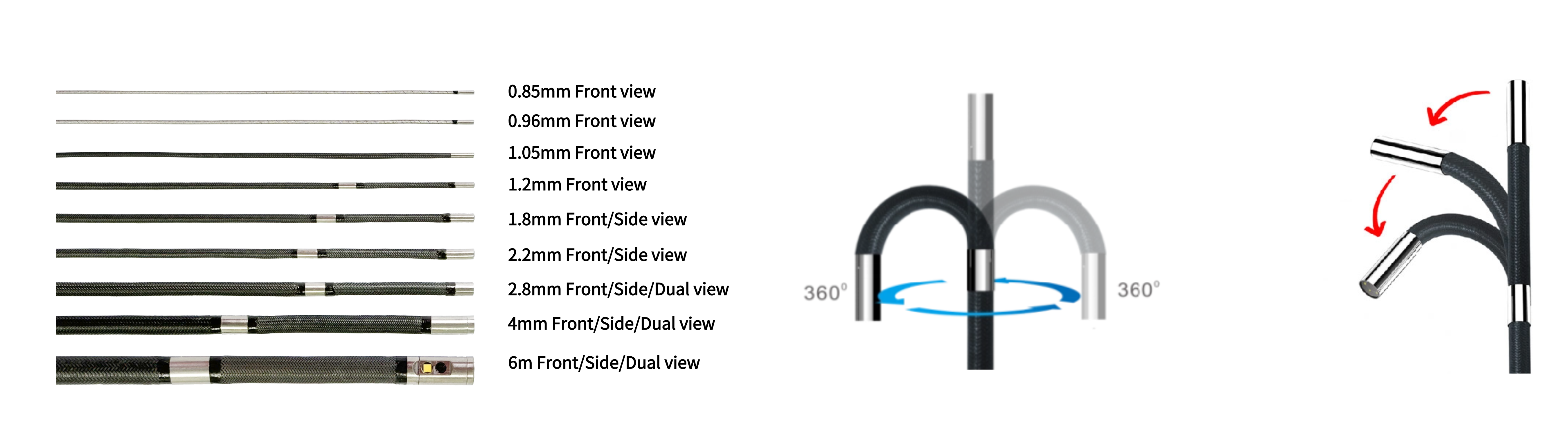

The company's technical department clearly stated that its mold channels cover multiple diameters—8 / 11 / 12 / 14.7 / 19 / 24 mm—with varying lengths, the longest approaching 2 meters. In addition, cinnabar markings are applied to the inner walls, requiring highly precise inspection to identify defects such as burrs and sand inclusion on the internal surfaces.

After extensive research and evaluation, DATAMATIC CNC ENGINEERING CO., LTD. ultimately selected the HD industrial videoscope from JOINWE. This solution successfully addressed the inspection challenges and enabled precise, reliable quality control of mold channels.

Before introducing the JOINWE industrial videoscope, DATAMATIC CNC ENGINEERING CO., LTD. faced multiple challenges in mold channel inspection. Traditional inspection methods either relied on manual visual checks - which are simply unable to reach the interior of long, small-diameter channels - or used conventional inspection equipment limited by image clarity and probe flexibility. Such equipment struggled to penetrate the interference caused by cinnabar markings on the inner walls, making it difficult to accurately identify tiny defects such as burrs and sand inclusion.

If defective molds were put into production, they would not only compromise the molding quality of injection products but could also accelerate mold wear, increase production costs, and even damage the company’s market reputation. As a result, finding an inspection solution capable of adapting to multiple channel specifications, delivering high-definition imaging, and offering strong anti-interference performance became an urgent requirement for DATAMATIC CNC ENGINEERING to enhance mold quality—ultimately leading to the adoption of the HD industrial videoscope from JOINWE.

In response to the specific inspection requirements of DATAMATIC CNC ENGINEERING CO., LTD., the JOINWE HD industrial videoscope demonstrated precise adaptability and outstanding inspection performance. Equipped with a high-definition camera and high image resolution, the system clearly captures fine details on the inner walls of mold channels. Even in the presence of cinnabar markings, it can accurately distinguish between markings and actual defects, effectively preventing misjudgment and missed detection.

At the same time, the device features a flexibly adjustable probe that accommodates multiple diameters ranging from 8 to 24 mm. For channels approaching 2 meters in length, the probe can easily advance deep into the interior, enabling full-length, blind-spot-free inspection. This comprehensive capability ensures complete coverage of all mold channel inspection scenarios at DATAMATIC CNC ENGINEERING, delivering reliable quality assurance powered by the JOINWE industrial videoscope.

In practical application, the efficiency of the JOINWE industrial videoscope has been fully demonstrated. Inspectors can complete pipeline inspections quickly using the handheld device, without the need for complex mold disassembly. This significantly shortens inspection time and greatly improves efficiency. When defects such as burrs or sand inclusion are detected, the system can record images and video in real time, providing accurate evidence for subsequent repair work and enabling technicians to quickly locate and resolve issues.

In addition, the device is simple and convenient to operate. It does not require a specialized technical team—ordinary inspection personnel can become proficient after brief training—further reducing inspection and operational costs for the company.

Since introducing the JOINWE industrial videoscope, DATAMATIC CNC ENGINEERING CO., LTD. has seen a significant improvement in defect detection rates for mold channels, effectively preventing defective molds from entering production and substantially increasing the pass rate of injection-molded products. The enhanced inspection efficiency has also accelerated mold production turnaround, helping the company improve overall manufacturing efficiency. According to the head of the technical department at DATAMATIC CNC ENGINEERING, the JOINWE industrial videoscope has precisely addressed the company’s mold channel inspection challenges and provided strong support for quality control, making it a highly valuable piece of industrial inspection equipment.

This successful collaboration between JOINWE and DATAMATIC CNC ENGINEERING fully demonstrates the core advantages of HD industrial videoscopes in mold inspection applications. Looking ahead, JOINWE will continue to deepen its expertise in the industrial inspection field, continuously optimize product performance, and provide precise and efficient inspection solutions for more enterprises—helping them build robust quality assurance systems and achieve high-quality development.

#IndustrialVideoscope #HDVideoscope #VideoscopeInspection #MoldChannelInspection #InjectionMold #NDT #PrecisionInspection #QualityControl #IndustrialInspection #JOINWE